5041 (LPM 510) Subminiature Compression

Capacity: 10 to 500 Lbs

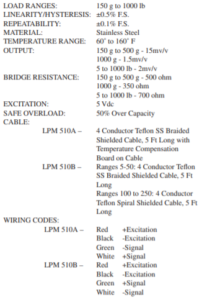

Model LPM 510 (compression only) subminiature load cell is designed to measure load ranges from 150 grams to 1000 pounds with a high frequency response rate. The subminiature dimensions, including diameters from 0.38″ to 0.75″ and heights of 0.13″ to 0.25″ allow these units to be easily incorporated into systems having limited space. A small (1.0″ long x 0.08″ thick circuit board on ranges 50 g – 1000 g) is included in each load cell’s lead wire cable for temperature compensation.

Note: Ranges 150G to 1000G lbs only available in LPM 510A style

- Tension/compression

- Wafer thin

- Up to 1,000lb

- High/low temp. option

- 150gms to 1,000lb

- Optional bottom cable exit

Related Products

View as :

G4610

Description >

The G4610 is a full-featured multipurpose, easy-to-use digital strain gauge & load cell meter ideal for weight and force measurement applications.

Model 3i, Model 3i – Basic Force/Torque Indicator

Description >

The 3i digital force/torque indicator is designed to work with a wide range of remote force and torque sensors. With exclusive Plug & Test (TM) technology, all calibration and configuration data is saved within the sensor’s smart connector, not the indicator, allowing for true interchangeability. In addition, all sensors are fully compatible with the advanced 5i force/torque indicator.

Model 5i, Model 5i – Advanced Force/Torque Indicator

Description >

The 5i advanced digital force/torque indicator is designed to work with a wide range of remote foce and torque sensors. With exclusive Plug & Test (TM) technology, all calibration and configuration data is saved within the sensor’s smart connector, not the indicator, allowing for tru interchangeability. In addition, all sensors are fully compatible with the more basic 3i force/torque indicator.

Model 7i, Model 7i – Professional Force/Torque Indicator

Description >

The 7i professional digital force/torque indicator is designed to work with a wide range of remote force and torque sensors. Exclusive Plug TestTM technology allows all calibration and configuration data to be saved within the sensor’s smart connector, not the indicator, allowing for true interchangeability. In addition to the 5i indicator, the 7i features high speed continuous data capture and storage, with memory for up to 5,000 readings, at an acquisition rate of up to 14,000 Hz. The 7i also features programmable footswitch sequencing, break detection, and 1st / 2nd peak detection. Coefficient of friction unit of measurement and a user-defined unit of measurement add flexibility for specialized applications. For productivity enhancement, the indicator also features automatic data output, data storage, and zeroing functions upon the completion of break detection, averaging, external trigger, and 1st / 2nd peak detection. The included MESURTM Lite data acquisition software tabulates continuous or single point data. Data saved in the indicator’s memory can also be downloaded in bulk. One-click export to Excel easily allows for further data manipulation.

View Datasheet

View Datasheet