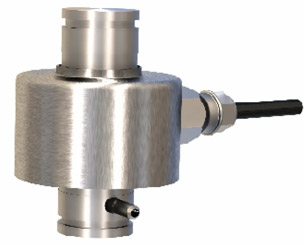

The first high capacity load cells designed, back in the mid 50’s were what is know today as “Canister” load cells. The design consisted of double diaphragms, which were brazed in place to reduce the effects of side and angular loads. These cells were typically hermetically sealed and very durable. They usually require slide plate assemblies and stay rods to prevent the introduction of additional side loads. These load cells were typically used in motor truck scales, rail road track scales and for tank weighing. Rocker column load cells, shear beams and double ended shear beams have subsequently replaced the need for Canister load cells. Canister load cells have been widely used and there are many thousands still in use. Group Four is in the ideal position to provide replacement units when needed.

Products

LRCN (5038) dual bridge load cell IP67

Capacity: .25-2

Description >

ATC (5000) Tension/Compression Compact Load Cell

Capacity: 1, 2, 5, 10, 25, 50klbs

Description >

RC (5030) Stainless Steel Rocker Column Load Cell IP69

Capacity: 5t to 50t

Description >

RCH (5031) Stainless Steel Digital Rocker Column IP68

Capacity: 30klbs

Description >

JALH (5033) Compression Canister Load Cell

Capacity: 10klb to 100klb

Description >

COLC (5038) Tension/Compression Load Cell

Capacity: 10klb

Description >

DTC (5043D) Digital Compression Canister Load Cell

Capacity: 10k to 50k

Description >